What is Beer?

Beer is an alcoholic beverage made from four primary ingredients: water, malted grains, hops, and yeast. Through fermentation, yeast converts the sugars from malted grains into alcohol and carbon dioxide, creating a wide range of beer styles with distinct flavours, aromas, and characteristics.

Introduction to Beer Brewing

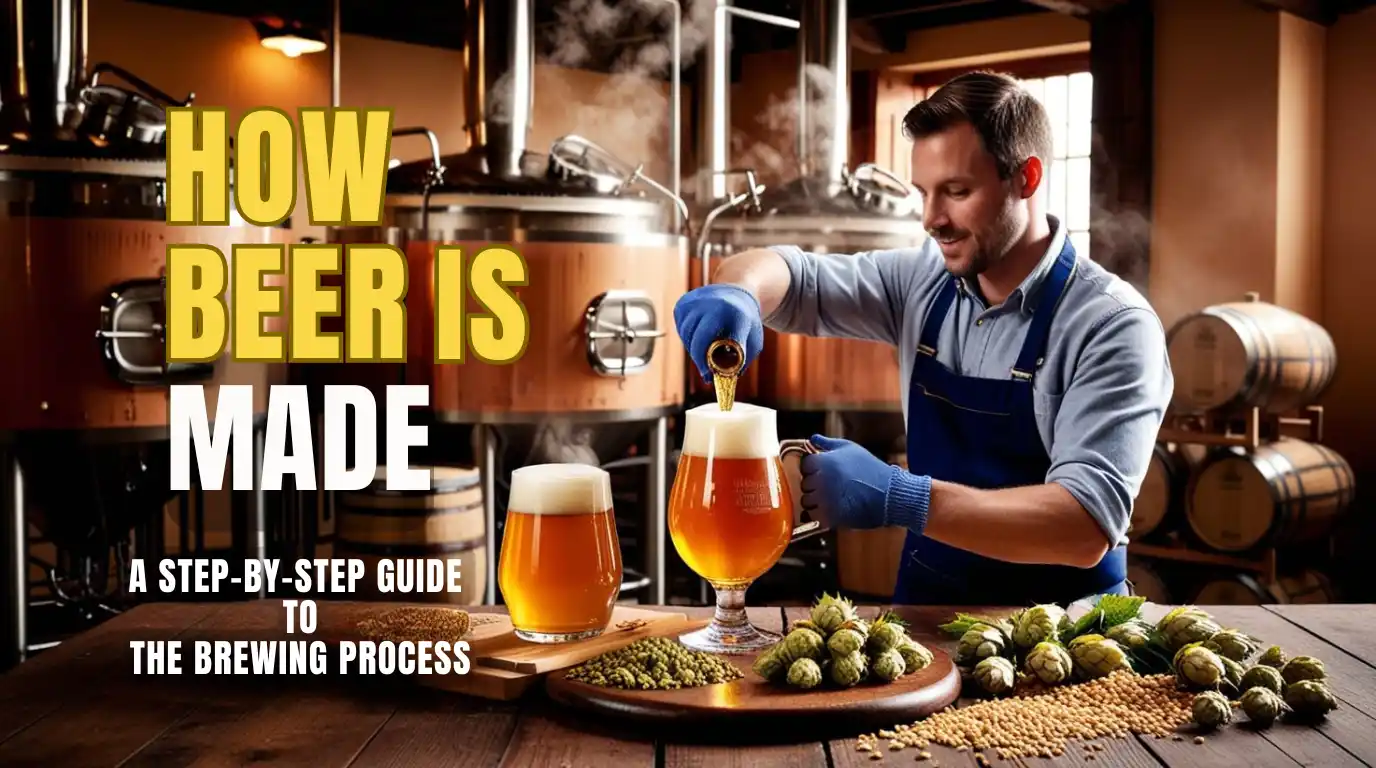

Beer brewing is an age-old process that has been refined over centuries to create a diverse range of beers enjoyed worldwide. The brewing process involves converting grains into fermentable sugars, which yeast then transforms into alcohol. Understanding these steps provides insight into the craftsmanship behind each pint.

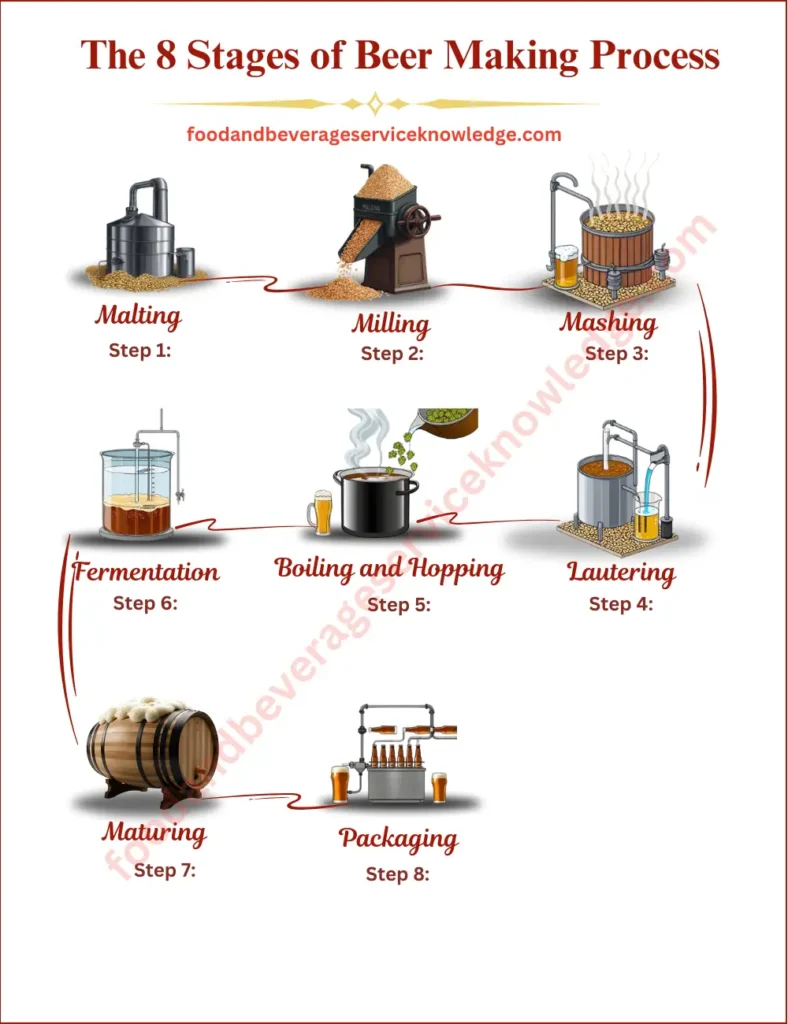

The brewing process consists of eight essential steps, each playing a crucial role in developing beer’s flavor, aroma, and alcohol content.

Beer has a rich history dating back thousands of years, evolving from ancient brewing techniques to modern craft innovations. Learn more about the history of beer on Wikipedia.”

Before You Begin: Brewing Overview

To simplify the brewing process, refer to this infographic, which outlines the 8 key steps of beer production for a clear and structured understanding.

The Essential Ingredients of Beer

Beer is made from just four key ingredients, but their careful combination and variation create an endless array of flavours and styles.

- Water – The primary component of beer, making up about 90% of the final product. The mineral content of water affects the beer’s taste, mouthfeel, and brewing characteristics.

- Malt – Typically derived from malted barley, this ingredient provides the essential fermentable sugars needed for alcohol production. Different malts contribute to the beer’s colour, body, and sweetness.

- Yeast – A crucial microorganism that converts sugars into alcohol and carbon dioxide through fermentation. The yeast strain used influences the beer’s flavour, determining whether it becomes an ale or a lager.

- Hops – These cone-shaped flowers add bitterness, aroma, and flavour to balance the sweetness of the malt. Different hop varieties contribute floral, citrus, piney, or earthy notes.

Want to see the beer brewing process in action? Watch this video to learn how raw ingredients transform into your favourite brew, step by step!

How Beer is Made: Step-by-Step Brewing Process

Beer brewing is a precise and well-structured process that transforms basic ingredients—grains, water, hops, and yeast—into a globally cherished beverage. Below are the eight key stages of brewing, each playing a crucial role in shaping the beer’s flavor, aroma, and quality.

Step 1: Malting

Malting is the first essential step in beer brewing, where grains—typically barley—are prepared for fermentation. This process converts the grain’s starches into fermentable sugars, which yeast will later transform into alcohol.

The Malting Process: Key Stages

- Steeping – Barley is soaked in water for 2–3 days, increasing its moisture content to around 45% to trigger germination.

- Germination – The grains sprout over 4–6 days, activating enzymes that break down starches into sugars.

- Kilning/Roasting – Germination is halted by drying the grains in a kiln. The level of roasting affects the malt’s flavour, aroma, and colour:

- Lightly kilned malts produce pale, crisp beers.

- Heavily roasted malts create darker beers with rich, complex flavours.

Educational Insight: The choice of malt plays a significant role in a beer’s final taste and appearance. Pale malts lead to lighter beers, while darker, roasted malts contribute to deep, robust flavours found in stouts and porters.

The malt variety used in brewing influences the beer’s character and aroma. Explore how different malt types are chosen for specific beer styles in this article by the Craft Beer & Brewing team. Visit Craft Beer & Brewing – Malt Varieties in Brewing

Step 2: Milling

After malting, the grains are milled or crushed to break open the husks, allowing for efficient sugar extraction during the next phase—mashing. This step is crucial for ensuring proper enzyme activity and maximizing the beer’s alcohol potential.

The Milling Process: Key Stages

- Setting the Mill – Adjustments are made based on the grain type and desired coarseness.

- Crushing the Grains – The malted grains are passed through the mill, cracking the husk and exposing starches.

- Grist Collection – The ground grains, now called grist, are gathered in a hopper and transferred to the mash tun.

Why Proper Milling Matters

- Too coarse → Poor sugar extraction, leading to lower alcohol content.

- Too fine → Can create a thick, gummy mash, making filtration difficult.

- Optimal milling → Ensures maximum starch conversion and influences the beer’s body, flavour, and alcohol level.

Educational Insight: Milling increases the malt’s surface area, allowing enzymes to efficiently break down starches during mashing. The precision of this step directly affects the beer’s fermentability, mouthfeel, and overall quality.

Step 3: Mashing

Mashing is the process of mixing the milled grains (grist) with hot water in a mash tun. This step activates enzymes in the malt, breaking down starches into fermentable sugars, which yeast will later convert into alcohol.

The mashing temperature plays a crucial role:

- 60–65°C (140–149°F) → Produces a lighter, drier beer (e.g., pilsners).

- 66–70°C (150–158°F) → Creates a fuller-bodied, sweeter beer (e.g., stouts, porters).

The result of mashing is a sugary liquid known as wort, which will be extracted in the next stage.

The Mashing Process: Key Stages

- Doughing-In – The grist is thoroughly mixed with hot water for even hydration.

- Saccharification – Enzymes convert starches into simpler sugars, forming wort.

- Resting – The mash is held at a stable temperature to ensure complete sugar extraction.

Educational Insight: Mash temperature directly affects the beer’s final body and sweetness. Lower temperatures lead to crisp, dry beers, while higher temperatures create richer, maltier flavours.

Also, read our guide on: Exploring the Different Types of Beer: Ales, Lagers, Sours & More

Step 4: Lautering

Lautering is the process of separating the wort (sugary liquid) from the solid grain particles after mashing. This step takes place in a lauter tun, where the mash is filtered through a bed of spent grains to clarify the wort.

To maximize sugar extraction, hot water (sparge water) is gently poured over the grains, rinsing out any remaining sugars. This ensures the wort retains as much fermentable sugar as possible, which directly affects the beer’s alcohol content.

The Lautering Process: Key Stages

- First Wort Runoff – The initial wort is collected after passing through the grain bed.

- Sparging – Hot water is sprayed over the grains to extract any remaining sugars.

- Wort Collection – The clarified wort is transferred to a brew kettle for boiling.

Why Lautering Matters

- Removes grain solids, preventing unwanted flavours in the final beer.

- Enhances brewing efficiency by extracting maximum sugars.

- Ensures a clear wort, crucial for beer clarity and taste.

Educational Insight: Lautering is a vital step in wort preparation, ensuring that the beer has the right sugar content for fermentation. Proper sparging leads to better efficiency and a balanced final product.

Lautering isn’t just about separating wort; it’s crucial for maximising sugar extraction. Find more detailed techniques on lautering to increase brewing efficiency from the Home Brewers Guild.Visit Home Brewers Guild – Lautering Efficiency

Step 5: Boiling and Hopping

Boiling is a crucial step in brewing, where the wort is heated for 60 to 90 minutes to sterilize it, remove unwanted compounds, and extract bitterness from hops. Hops are the flowering cones of the hop plant, responsible for balancing the sweetness of the malt with bitterness, aroma, and flavour.

The Role of Hops in Beer

- Early hop additions → More bitterness

- Mid-boil additions → Balanced flavor

- Late or post-boil additions → Enhanced aroma

The bitterness of beer is measured in IBUs (International Bitterness Units), with higher IBUs indicating more bitterness. Hop varieties vary globally, with American hops imparting citrus and pine notes, while European hops offer earthy, herbal flavours.

Key Stages of Boiling and Hopping

- Boiling the Wort – The wort is heated to a rolling boil to sterilize it.

- Adding Hops – Hops are added at different times to adjust bitterness, flavor, and aroma.

- End of Boil – Boiling stops once the desired balance of bitterness and flavor is achieved.

Educational Insight: The timing of hop additions determines whether hops contribute bitterness, aroma, or both. Boiling also helps concentrate flavours and enhances the stability and shelf life of the beer.

Step 6: Fermentation

After boiling, the wort is rapidly cooled and transferred to a fermentation tank, where yeast is added to convert sugars into alcohol and carbon dioxide. This step is crucial in defining the beer’s flavour, aroma, and alcohol content.

Types of Fermentation

Beer fermentation can be categorized into two main types based on yeast behaviour and fermentation temperature:

1. Top Fermentation (Ale Fermentation)

- Uses Saccharomyces cerevisiae yeast

- Ferments at warmer temperatures (15-24°C / 59-75°F)

- Yeast rises to the top of the fermentation tank

- Produces fruity and complex flavors

- Common in beers like Pale Ales, Stouts, and Wheat Beers

2. Bottom Fermentation (Lager Fermentation)

- Uses Saccharomyces pastorianus yeast

- Ferments at cooler temperatures (7-13°C / 45-55°F)

- Yeast settles at the bottom of the fermentation tank

- Results in clean, crisp, and smooth flavours

- Found in beers like Pilsners, Lagers, and Bocks

Key Stages of Fermentation

- Wort Cooling – The wort is rapidly cooled to a temperature suitable for yeast.

- Yeast Pitching – Yeast is added, beginning the fermentation process.

- Primary Fermentation – Yeast converts sugars into alcohol and carbon dioxide.

Educational Insight: The fermentation method (Top vs. Bottom) directly influences the beer’s characteristics. Ales, using top fermentation, produce richer, fruitier notes, while lagers, through bottom fermentation, create a smoother, crisper taste.

Step 7: Maturing

After fermentation, beer enters the maturation phase, where it conditions for several days to several months, depending on the beer style. This step refines the beer’s flavour, clarity, and stability, ensuring a well-balanced final product.

Maturation Time Based on Beer Type

- Lagers: Require a longer maturation period of 4 to 8 weeks at cold temperatures (0-4°C / 32-39°F) for a clean, crisp taste.

- Ales: Mature faster, typically within 1 to 3 weeks at warmer temperatures (10-16°C / 50-61°F), producing bold, fruity flavours.

- Strong Beers & Speciality Brews: Some high-alcohol beers (e.g., barleywines, stouts) may age for several months to years to enhance complexity.

Essential Stages of Maturing

- Cold Storage – Beer is aged at a controlled temperature for the required time.

- Dry-Hopping (Optional) – Additional hops may be added for aroma enhancement.

- Clarification – Sediments settle, resulting in a clearer beer.

Educational Insight: Maturation allows unwanted flavours to mellow and enhances aroma, mouthfeel, and stability. Lagers need longer cold storage, while ales mature quicker with a fruitier profile. Some beers are bottle-conditioned, continuing to evolve in flavour over time.

Step 8: Packaging

The final stage of the brewing process is packaging, where the beer is prepared for distribution and consumption. Whether it’s bottled, canned, or kegged, proper packaging ensures the beer retains its freshness, carbonation, and flavour.

Packaging Methods & Their Benefits

- Bottles: Traditional and widely used, but transparent and green bottles offer less protection against light exposure.

- Cans are becoming increasingly popular as they provide better protection from light and oxygen, preserving the beer’s flavour longer.

- Kegs: Often used for draft beer, keeping it fresher for longer with minimal oxidation.

Packaging Process

- Filtration (Optional) – Beer may be filtered to remove any remaining yeast or sediment.

- Carbonation – CO₂ is added artificially or naturally in the bottle/can.

- Sealing & Labelling – Containers are sealed, labelled, and prepared for distribution.

- Pasteurisation (Optional) – Some beers are heat-treated to extend shelf life, while others remain unpasteurized for a fresher taste.

Educational Insight: Light and oxygen exposure can degrade beer quality. Cans are gaining popularity among craft brewers due to their superior ability to block light, keeping beer fresher for longer.

How Brewing Techniques Vary Between Beer Styles

While the brewing process follows the same eight steps, the techniques and ingredients used differ depending on the beer style, impacting taste, aroma, and appearance.

Lagers vs. Ales

- Lagers: Brewed at cooler temperatures (45-55°F / 7-13°C) using bottom-fermenting yeast, resulting in a crisp, clean taste.

- Ales: Fermented at warmer temperatures (60-75°F / 15-24°C) with top-fermenting yeast, creating fruity, complex flavours.

Stouts vs. IPAs

- Stouts: Made with roasted malts, producing deep, coffee-like flavours.

- IPAs (India Pale Ales): Characterised by strong hop bitterness and aroma. Techniques like late hopping and dry hopping are used to enhance flavour without excessive bitterness.

Wheat Beers

- Brewed with a high proportion of wheat, creating a lighter body and hazy appearance.

- Typically undergo a shorter fermentation period, leading to a fresh, fruity taste.

Conclusion

Beer brewing is a carefully crafted process that transforms simple ingredients into diverse and flavorful beverages. From malting to packaging, each step plays a crucial role in shaping a beer’s taste, aroma, and quality. Whether it’s a crisp lager, a hoppy IPA, or a rich stout, the brewing techniques and ingredients define each style’s unique character. Understanding this process enhances appreciation for every sip. Cheers! ????

Related:

This article was written by Saswata Banerjee, the creator of Food and Beverage Service Knowledge, based on 8+ years of experience in the hospitality industry.